Parts Involved

Diesel injector nozzles are spring-loaded closed valves that spray fuel directly into the combustion chamber or precombustion chamber when the injector is opened. Injector nozzles are threaded or clamped into the cylinder head, one for each cylinder, and are replaceable as an assembly.

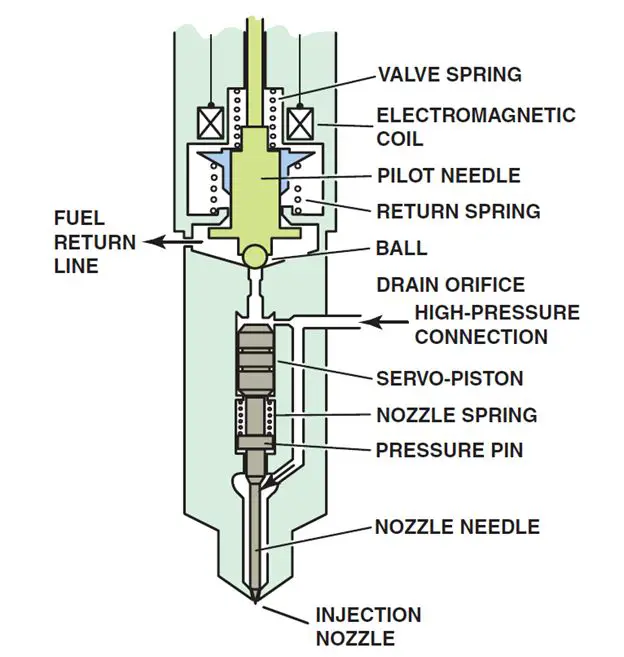

The tip of the injector nozzle has many holes to deliver an atomized spray of diesel fuel into the cylinder of the Engine. Parts of a diesel injector nozzle include:

- Heat shield. This is the outer shell of the injector nozzle and may have external threads where it seals in the cylinder head.

- Injector body. This is the inner part of the nozzle and contains the injector needle valve and spring, and threads into the outer heat shield.

- Diesel injector needle valve. This precision machined valve and the tip of the needle seal against the injector body when it is closed. When the valve is open, diesel fuel is sprayed into the combustion chamber. This passage is controlled by a computer-controlled solenoid on diesel engines equipped with computer-controlled injection.

- Injector pressure chamber. The pressure chamber is a machined cavity in the injector body around the tip of the injector needle. Injection pump pressure forces fuel into this chamber, forcing the needle valve open.

Diesel Injector Nozzle Operation

The electric solenoid attached to the injector nozzle is computer controlled and opens to allow fuel to flow into the injector pressure chamber.

The fuel flows down through a fuel passage in the injector body and into the pressure chamber. The high fuel pressure in the pressure chamber forces the needle valve upward, compressing the needle valve return spring and forcing the needle valve open. When the needle valve opens, diesel fuel is discharged into the combustion chamber in a hollow cone spray pattern. Learn more about Engine Lubrication & Cooling Systems Here.

Any fuel that leaks past the needle valve in the Engine returns to the fuel tank through a return passage and line.

Next Steps towards ASE Certification

Now that you’re familiar with Diesel Injector Nozzles, try out our free Automotive Service Excellence Tests to see how much you know!

![ASE Certification Training HQ - Free ASE Practice Tests [Updated 2021]](https://asecertificationtraining.com/wp-content/themes/simplefolio/images/ASE Certification Logo.png)