Types of Systems

Coolant flows through the engine in one of the following ways.

- Parallel flow system. In the parallel flow system, coolant flows into the block under pressure and then crosses the head gasket to the head through main coolant passages beside each cylinder.

- Series flow system. In the series flow system, the coolant flows around all the cylinders on each bank. All the coolant flows to the rear of the block, where large main coolant passages allow the coolant to flow across the head gasket. The coolant then enters the rear of the heads. In the heads, the coolant flows forward to a crossover passage on the intake manifold outlet at the highest point in the engine cooling passage. This is usually located at the front of the engine. The outlet is either on the heads or in the intake manifold.

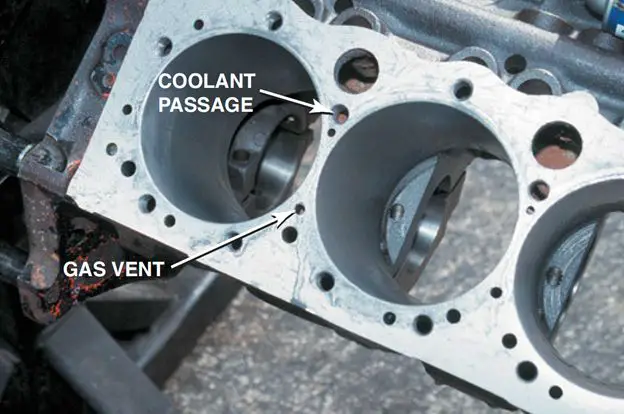

- Series-parallel flow system. Some engines use a combination of these two coolant flow systems and call it a seriesparallel flow system. Any steam that develops will go directly to the top of the radiator. In series flow systems, bleed holes or steam slits in the gasket, block, and head perform the function of letting out the steam.

A Chevrolet V-8 Block that shows the large coolant holes and the smaller gas vent or bleed holes that must match the head gasket when the engine is assembled.

Coolant Flow and Head Gasket Design

Most V-type engines use cylinder heads that are interchangeable side to side, but not all engines. Therefore, based on the design of the cooling system and flow through the engine, it is very important to double check that the cylinder head is matched to the block and that the head gasket is installed correctly (end for end) so that all of the cooling passages are open to allow the proper flow of coolant through the system.

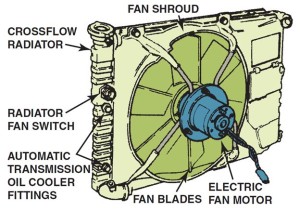

Cooling Fans

Electronically Controlled Cooling Fan

Two types of electric cooling fans used on many engines include:

- One two-speed cooling fan

- Two cooling fans (one for normal cooling and one for high heat conditions)

The PCM commands low-speed fans on under the following conditions.

- Engine coolant temperature (ECT) exceeds approximately 223°F (106°C).

- A/C refrigerant pressure exceeds 190 PSI (1,310 kPa).

- After the vehicle is shut off, the engine coolant temperature at key-off is greater than 284°F (140°C) and system voltage is more than 12 volts. The fan(s) will stay on for approximately three minutes.

The PCM commands the high-speed fan on under the following conditions.

- Engine coolant temperature (ECT) reaches 230°F (110°C).

- A/C refrigerant pressure exceeds 240 PSI (1,655 kPa).

- Certain diagnostic trouble codes (DTCs) set.

To prevent a fan from cycling on and off excessively at idle, the fan may not turn off until the ignition switch is moved to the off position or the vehicle speed exceeds approximately 10 mph (16 km/h).

Many rear-wheel-drive vehicles and all transverse engines drive the fan with an electric motor.

- NOTE: Most electric cooling fans are computer controlled. To save energy, most cooling fans are turned off whenever the vehicle is traveling faster than 35 mph (55 km/h). The ram air caused by the vehicle speed is enough to keep the radiator cool. Of course, if the computer senses that the temperature is still too high, the computer will turn on the cooling fan, to “high,” if possible, in an attempt to cool the engine to avoid severe engine damage.

Warning: Some electric cooling fans can come on after the engine is off without warning. Always keep hands and fingers away from the cooling fan blades unless the electrical connector has been disconnected to prevent the fan from coming on. Always follow all warnings and cautions.

Thermostatic Fins

On some rear-wheel-drive vehicles, a thermostatic cooling fan is driven by a belt from the crankshaft. It turns faster as the engine turns faster. Generally, the engine is required to produce more power at higher speeds. Therefore, the cooling system will also transfer more heat. Increased fan speed aids in the required cooling. Engine heat also becomes critical at low engine speeds in traffic where the vehicle moves slowly. The thermostatic fan is designed so that it uses little power at high engine speeds and minimizes noise. Two types of thermostatic fans include:

- Silicone coupling. The silicone coupling fan drive is mounted between the drive pulley and the fan. HINT: When diagnosing an overheating problem, look carefully at the cooling fan. If silicone is leaking, then the fan may not be able to function correctly and should be replaced.

- Thermostatic spring. A second type of thermal fan has a thermostatic spring added to the silicone coupling fan drive. The thermostatic spring operates a valve that allows the fan to freewheel when the radiator is cold. As the radiator warms to about 150°F (65°C), the air hitting the thermostatic spring will cause the spring to change its shape. The new shape of the spring opens a valve that allows the drive to operate like the silicone coupling drive. When the engine is very cold, the fan may operate at high speeds for a short time until the drive fluid warms slightly. The silicone fluid will then flow into a reservoir to let the fan speed drop to idle.

The fan is designed to move enough air at the lowest fan speed to cool the engine when it is at its highest coolant temperature. The fan shroud is used to increase the cooling system efficiency.

Tech Tip: Be Sure to Always Use a Fan Shroud

A fan shroud forces the fan to draw air through the radiator. If a fan shroud is not used, then air is drawn from around the fan and will reduce the airflow through the radiator. Many overheating problems are a result of not replacing the factory shroud after engine work or body repair work to the front of the vehicle.

Next Steps towards ASE Certification

Now that you’re familiar with Coolant Flow in the Engine, try out our free Automotive Service Excellence Tests to see how much you know!

![ASE Certification Training HQ - Free ASE Practice Tests [Updated 2021]](https://asecertificationtraining.com/wp-content/themes/simplefolio/images/ASE Certification Logo.png)