A diesel engine injection pump is used to increase the pressure of the diesel fuel from very low values from the lift pump to the extremely high pressures needed for injection. Ready for the advanced course? Test your knowledge of A1 – Engines Here.

Need for High-Pressure Fuel Pump

- The lift pump is a low-pressure, high-volume pump.

- The high-pressure injection pump is a high-pressure, low-volume pump.

Injection pumps are usually driven by a gear off the camshaft at the front of the engine. As the injection pump shaft rotates, the diesel fuel is fed from a fill port to a high-pressure chamber. If a distributor type injection pump is used, the fuel is forced out of the injection port to the correct injector nozzle through the high-pressure line.

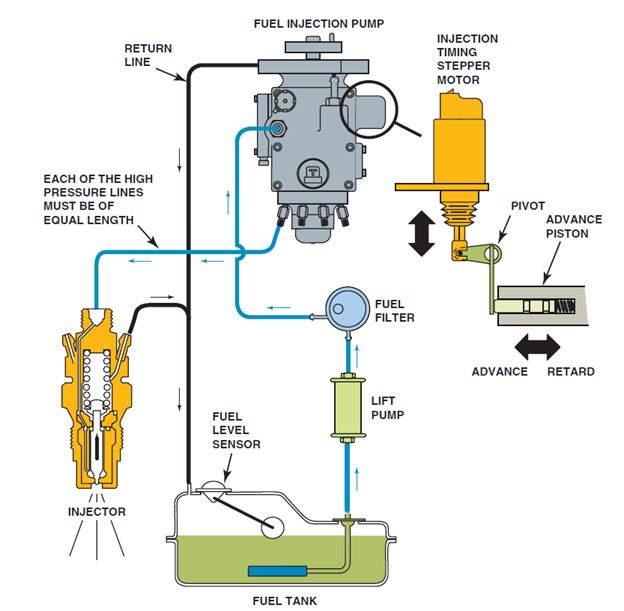

A schematic of a Standadyne diesel fuel-injection pump assembly showing all of the related components.

Distributor Injection Pump

A distributor diesel injection pump is a high-pressure pump assembly with lines leading to each individual injector. The high-pressure lines between the distributor and the injectors must be the exact same length to ensure proper injection timing. The high-pressure fuel causes the injectors to open. Due to the internal friction of the lines, there is a slight delay before fuel pressure opens the injector nozzle.

The injection pump itself creates the injection advance needed for engine speeds above idle often by using a stepper motor attached to the advance piston, and the fuel is then discharged into the lines.

Next Steps towards ASE Certification

Now that you’re familiar with Standadyne diesel fuel-injection pump assemblies, try out our free Automotive Service Excellence Tests to see how much you know!

![ASE Certification Training HQ - Free ASE Practice Tests [Updated 2021]](https://asecertificationtraining.com/wp-content/themes/simplefolio/images/ASE Certification Logo.png)