Heater Cores Purpose and Function

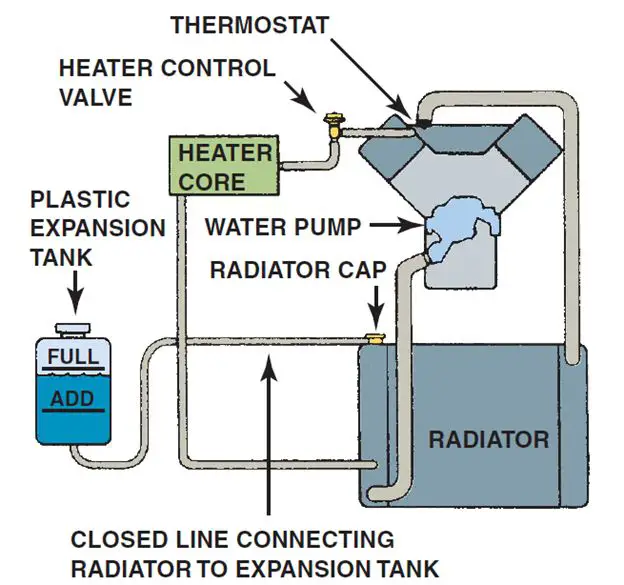

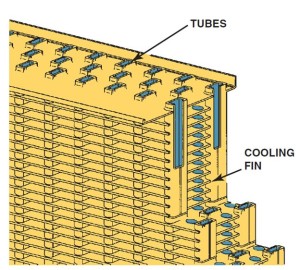

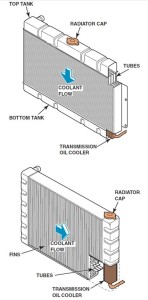

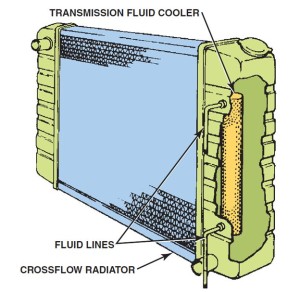

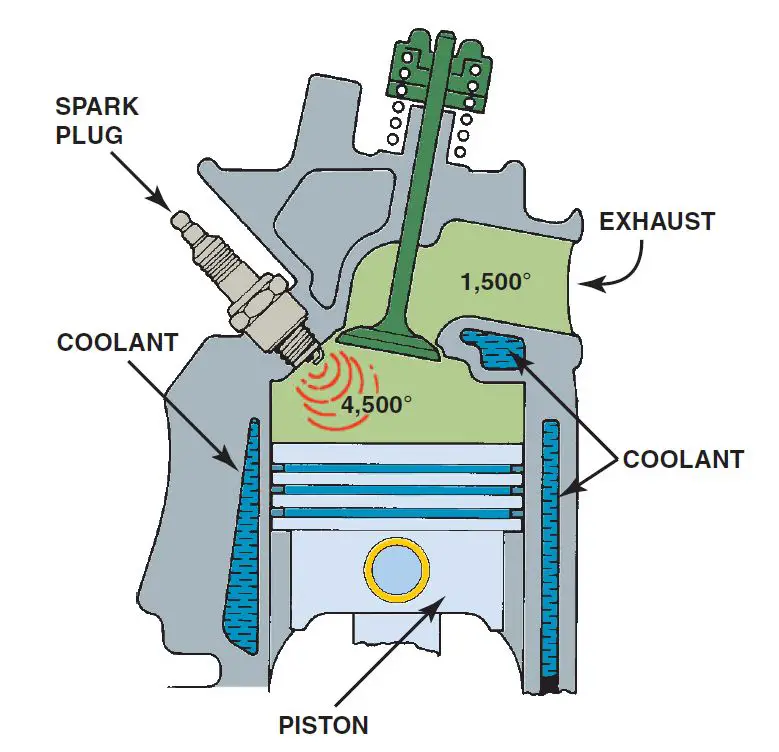

Most of the heat absorbed from the engine by the cooling system is wasted. Some of this heat, however, is recovered by the vehicle heater. Heated coolant is passed through tubes in the small core of the heater. Air is passed across the heater fins and is then sent to the passenger compartment. In some vehicles, the heater and air conditioning work in series to maintain vehicle compartment temperature.

Heater Problem Diagnosis

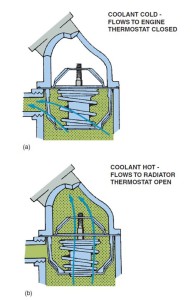

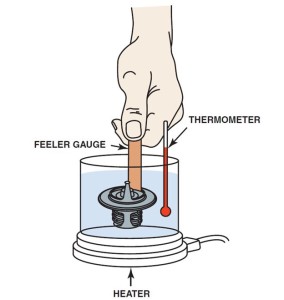

When the heater does not produce the desired amount of heat, many owners and technicians replace the thermostat before doing any other troubleshooting. It is true that a defective thermostat is the reason for the engine not to reach normal operating temperature, but there are many other causes besides a defective thermostat that can result in lack of heat from the heater. To determine the exact cause, follow this procedure.

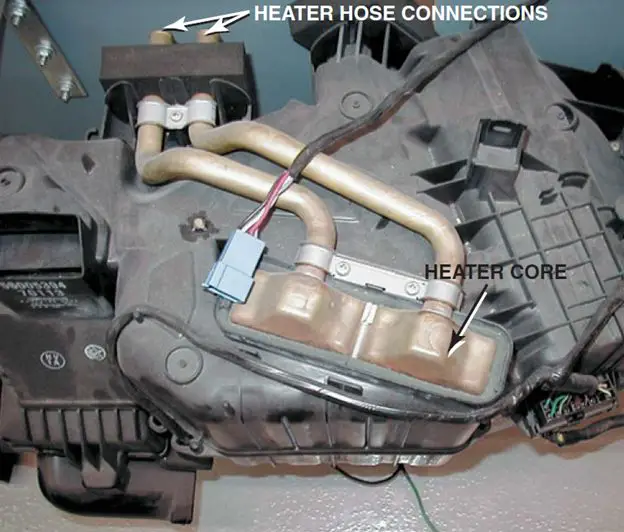

A typical heater core installed in a heating, ventilation, and air-conditioning (HVAC) housing assembly.

STEP 1

After the engine has been operated, feel the upper radiator hose. If the engine is up to proper operating temperature, the upper radiator hose should be too hot to hold. The hose should also be pressurized.

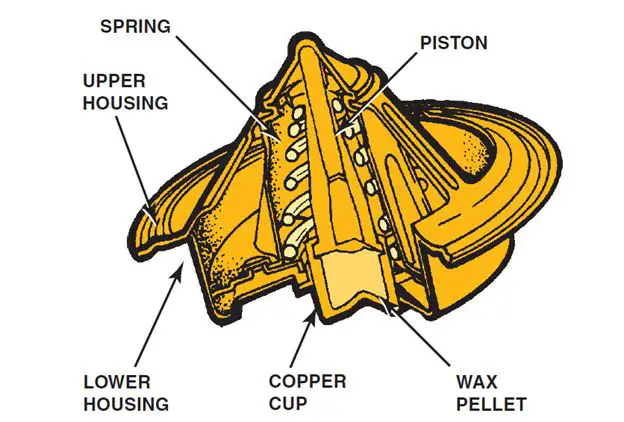

- If the hose is not hot enough, replace the thermostat.

- If the hose is not pressurized, test or replace the radiator pressure cap if it will not hold the specified pressure.

- If okay, see step 2.

STEP 2

With the engine running, feel both heater hoses. (The heater should be set to the maximum heat position.) Both hoses should be too hot to hold. If both hoses are warm (not hot) or cool, check the heater control valve for proper operation (if equipped). If one hose is hot and the other (return) is just warm or cool, remove both hoses from the heater core or engine and flush the heater core with water from a garden hose.

STEP 3

If both heater hoses are hot and there is still a lack of heating concern, then the fault is most likely due to an airflow blend door malfunction. Check service information for the exact procedure to follow.

HINT: Heat from the heater that “comes and goes” is most likely the result of low coolant level. Usually with the engine at idle, there is enough coolant flow through the heater. At higher engine speeds, however, the lack of coolant through the heads and block prevents sufficient flow through the heater.

Cooling System Testing

Visual Inspection

Many cooling system faults can be found by performing a thorough visual inspection. Items that can be

inspected visually include:

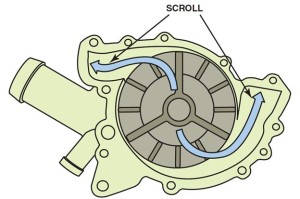

- Water pump drive belt for tension or faults

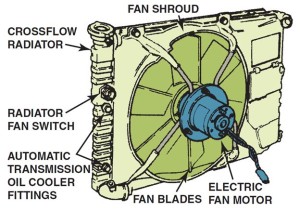

- Cooling fan for faults

- Heater and radiator hoses for condition and leaks

- Coolant overflow or surge tank coolant level

- Evidence of coolant loss

- Radiator condition

A heavily corroded radiator from a vehicle that was overheating. A visual inspection discovered that the corrosion had eaten away many of the cooling fins, yet did not leak. This radiator was replaced and it solved the overheating problem.

Pressure Testing

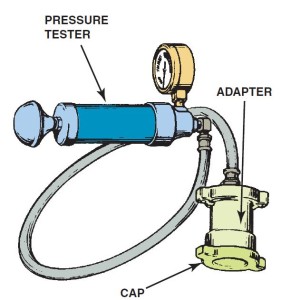

Pressure testing using a hand-operated pressure tester is a quick and easy cooling system test. The radiator cap is removed (engine cold!) and the tester is attached in the place of the radiator cap. By operating the plunger on the pump, the entire cooling system is pressurized.

- CAUTION: Do not pump up the pressure beyond that specified by the vehicle manufacturer. Most systems should not be pressurized beyond 14 PSI (100 kPa). If a greater pressure is used, it may cause the water pump, radiator, heater core, or hoses to fail.

If the cooling system is free from leaks, the pressure should stay and not drop. If the pressure drops, look for evidence of leaks anywhere in the cooling system, including:

- Heater hoses

- Radiator hoses

- Radiator

- Heater core

- Cylinder head

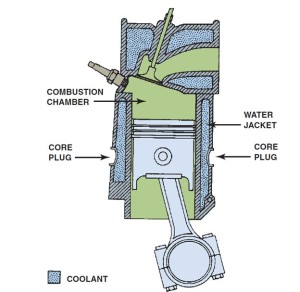

- Core plugs in the side of the block or cylinder head

The pressure cap should be checked for proper operation using a pressure tester as part of the cooling system diagnosis.

Pressure testing should be performed whenever there is a leak or suspected leak. The pressure tester can also be used to test the radiator cap. An adapter is used to connect the pressure tester to the radiator cap. Replace any cap that will not hold pressure.

Coolant Dye Leak Testing

One of the best methods to check for a coolant leak is to use a fluorescent dye in the coolant, one that is specifically designed for coolant. Operate the vehicle with the dye in the coolant until the engine reaches normal operating temperature. Use a black light to inspect all areas of the cooling system. When there is a leak, it will be easy to spot because the dye in the coolant will be seen as bright green. Pressure testing the cooling system. A typical hand-operated pressure tester applies pressure equal to the radiator cap pressure. The pressure should hold; if it drops, this indicates a leak somewhere in the cooling system. An adapter is used to attach the pump to the cap to determine if the radiator can hold pressure, and release it when pressure rises above its maximum rated pressure setting.

Next Steps towards ASE Certification

Now that you’re familiar with Heater Cores: Problem Diagnosis, Inspection, Pressure, and Dye Testing, try out our free Automotive Service Excellence Tests to see how much you know!

![ASE Certification Training HQ - Free ASE Practice Tests [Updated 2021]](https://asecertificationtraining.com/wp-content/themes/simplefolio/images/ASE Certification Logo.png)